Satyajit Ghana

Published on August 11, 2025

In today’s fast-paced real estate, infrastructure, and construction environment, owning the right information about your asset at the right time can make the difference between operational efficiency and costly downtime. While many in the Architecture, Engineering, and Construction industry are familiar with Building Information Modelling (BIM) for design and planning, a new wave of technology is revolutionising post-construction asset management - the Digital Twin.

A Digital Twin is not for the design table. It is not a pre-construction or under-construction tool. Instead, it is built for projects that are already constructed, commissioned, and operational - helping owners, operators, and facility managers maximize the performance and lifespan of their assets.

What is a Digital Twin in the Construction Industry?

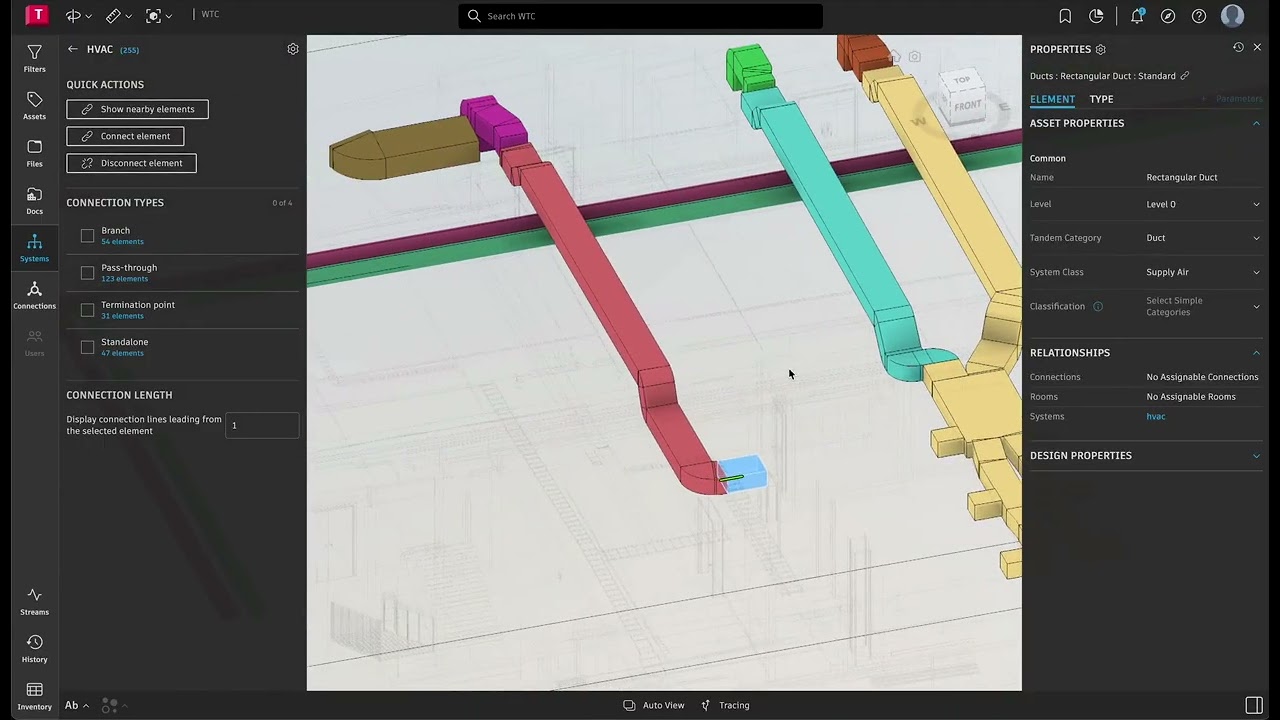

In simple terms, a Digital Twin is a virtual, data-rich replica of a completed physical asset - be it a high-rise building, a bridge, a factory, or a public infrastructure network. It continuously reflects the real-world condition, performance, and usage of the asset by integrating live and historical data from sensors, IoT devices, maintenance logs, inspection reports, and other operational systems.

Unlike BIM, which is static and primarily used before or during construction, a Digital Twin is dynamic and operational. It evolves in real time alongside your asset, offering a single, accurate source of truth for every decision you make about its upkeep, performance, and future modifications.

Where Digital Twins Fit in the Asset Lifecycle

Digital Twins deliver value after your project is complete—starting at commissioning and extending across decades of use.

1. Handover & Commissioning

2. Day-to-Day Operations

3. Predictive & Preventive Maintenance

4. Renovations, Retrofits & Expansions

Key Benefits of Digital Twins for Built & Operational Projects

For completed projects, a Digital Twin is not just a visual tool—it is a strategic operations platform.

1. Real-Time Asset Performance Monitoring

A Digital Twin allows facility managers to keep track of the health and performance of the asset continuously. For example, in a luxury residential tower in Mumbai, a Digital Twin can help track HVAC system efficiency, ensuring consistent comfort for residents while optimising power usage.

2. Predictive Maintenance

Instead of waiting for an equipment failure, operators can use sensor data from the Digital Twin to forecast when maintenance is required. For instance, in a commercial IT park, vibration analysis of lifts can signal the need for servicing weeks before a breakdown, preventing costly downtime.

3. Optimised Resource Use

By analysing usage patterns, owners can identify and eliminate waste—whether it’s underutilised office space, excess lighting in low-traffic zones, or inefficient water usage in a manufacturing plant.

4. Faster Compliance & Easier Audits

All maintenance records, inspection reports, and upgrade histories are stored digitally in one place. For example, a government-owned hospital can present full compliance documentation during safety audits within minutes, avoiding lengthy manual searches.

5. Informed Renovation & Upgrade Planning

When retrofitting an existing facility—such as adding solar panels to a corporate headquarters—a Digital Twin ensures planners know exactly how the building is currently structured, avoiding unnecessary demolition or rework.

Real-World Use Cases in India & Globally

Digital Twins are no longer experimental—they are actively transforming the way built assets are operated worldwide.

- Smart Building Management – Commercial office parks in Bengaluru are adopting Digital Twins to track energy use, reduce carbon footprint, and improve tenant comfort.

- Infrastructure – Metro stations in Delhi have begun exploring digital models to manage passenger flow, safety checks, and maintenance schedules more effectively.

- Singapore – Maintains city-scale Digital Twins for operational planning, traffic management, and utilities monitoring.

- United Kingdom – Uses Digital Twins for critical infrastructure like water treatment plants to optimise performance and extend service life.

Why Digital Twins Are a Game-Changer for Operational Assets

In the life of a building or infrastructure project, construction is just the beginning. The real cost, effort, and responsibility lie in its decades of operation. This is where the Digital Twin shines - it helps you:

For asset owners, facility managers, and government bodies, a Digital Twin offers the confidence that every decision is based on accurate, current, and complete information.

How Inkers Technologies Adds Value

At Inkers Technologies, we specialise in creating precise, data-rich Digital Twins for completed projects across real estate, infrastructure, and industrial sectors.

Our approach combines:

To deliver world-class Digital Twin capabilities, Inkers Technologies has collaborated with Autodesk Tandem, a leading platform for Digital Twin technology. This partnership allows us to not only create high-quality Digital Twins but also manage and integrate them seamlessly into your company’s operational workflows—ensuring smooth adoption, reliable performance, and measurable ROI for your built assets.

Whether you operate a manufacturing plant in Gujarat, manage a public transit system in a metro city, or oversee a chain of commercial buildings, our Digital Twin solutions—powered by Autodesk Tandem—give you the visibility and control you need to run your asset efficiently.

Conclusion

A Digital Twin is not just a technology—it’s an operational strategy for the life of your asset. From the moment your project is handed over to the day it’s retired or repurposed, a Digital Twin ensures you make decisions based on facts, not guesswork.

Ready to take control of your asset’s future?

Discover how Inkers Technologies’ Digital Twin solutions, in collaboration with Autodesk Tandem, can enhance performance, reduce costs, and extend the lifespan of your built projects. Turn your built project into a living, data-driven asset. Explore Digital Twin solutions with Inkers Technologies today.